After completion of the clay sculpture the piece goes through a casting process whereby a solid cast is produced from the clay master.

-

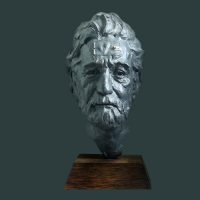

Polyester resin is mixed with a pure bonze powder, a skin of which is painted onto the inside of a silicon mold. this is reinforced with weighted resin to produce a robust cast. This method captures every detail, fingerprint and tooling mark from the original clay. The work is then demolded, chased to remove any unwanted marks and finally patinated using black graphite wax with a light verdigris wax tone to produce a traditional “Penny Black” finish.

-

For the smaller, limited edition pieces the works are cast solid using a vacuum casting method which allows for air free copies.

-

I can arrange to have any of the works foundry cast using the traditional “cire perdu” or “lost wax” process although this method adds considerable expense.